Choosing the Right Film for Glass Lamination: EVA vs. PVB vs. Ionoplast

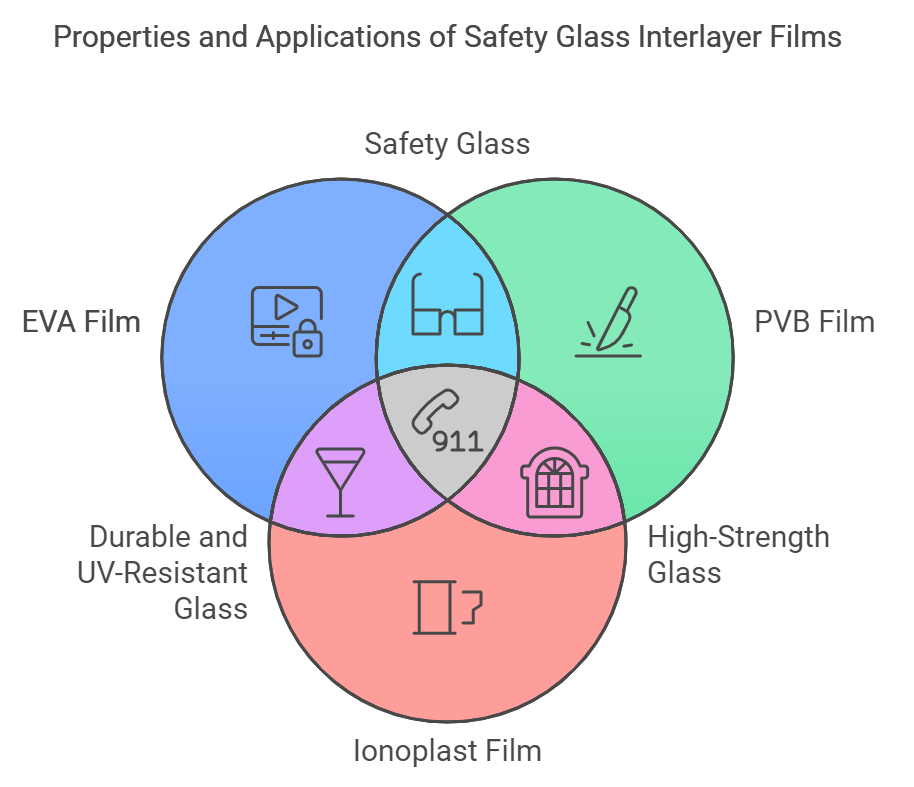

When it comes to safety glass applications, selecting the right interlayer film is crucial. Whether for architecture, automotive, or specialty glass projects, each interlayer film offers distinct characteristics that make it suitable for specific applications. As a trusted supplier of high-strength interlayer film for safety glass, Suzhou Xiaoshi Technology Co., Ltd. provides a range of options, including EVA, PVB, and Ionoplast films. This guide will outline the advantages, limitations, and ideal applications for each type, helping you make an informed choice for your glass lamination needs.

1. EVA Film: Versatile and Durable

Ethylene-Vinyl Acetate (EVA) film is a popular choice in glass lamination due to its flexibility, UV resistance, and strong adhesion to glass surfaces. EVA film is often chosen for applications that require outdoor durability, such as building facades, skylights, and solar panels. Here’s why EVA film may be a suitable option for certain safety glass applications:

l UV Resistance: EVA is highly resistant to ultraviolet (UV) light, making it ideal for outdoor use where exposure to sunlight is high. This UV resistance helps prevent discoloration and degradation over time, ensuring the longevity of laminated glass in exterior applications.

l Durability in Extreme Environments: EVA film performs well in extreme temperatures and moisture, making it suitable for regions with variable climates. This quality allows EVA to maintain its integrity without delaminating or becoming brittle in fluctuating weather conditions.

l Cost-Effectiveness: Compared to other interlayer films, EVA tends to be more cost-effective, especially for large projects with high film consumption.

However, EVA may not be the ideal choice for applications that require very high impact resistance, as it is generally less robust than some other interlayer options.

Best Applications: EVA film is often used in architectural glass applications, such as curtain walls and facades, solar panels, and decorative glass, where UV stability and moderate impact resistance are priorities.

2. PVB Film: High Impact Resistance and Versatility

Polyvinyl Butyral (PVB) is a widely used interlayer film in both architectural and automotive safety glass. Known for its high impact resistance, PVB film creates a strong bond with glass, preventing shattering on impact and ensuring high safety standards.

l Enhanced Safety Features: PVB is specifically engineered for high impact resistance, making it an excellent choice for applications where safety is paramount. Its structure allows glass to hold together upon impact, reducing the risk of injury from shattered glass.

l Clear Visual Clarity: PVB film offers high optical clarity, which is important for applications requiring maximum transparency, such as vehicle windshields or large building windows.

l Sound Dampening Properties: PVB has sound insulation qualities, making it ideal for areas where noise reduction is important, such as office buildings and residential complexes in urban settings.

However, PVB is less resistant to moisture and UV exposure than EVA, so it is better suited for indoor or controlled environments unless paired with additional protection layers.

Best Applications: PVB is a preferred option for automotive windshields, skylights, and large building windows, where high strength and transparency are essential for safety and visibility.

3. Ionoplast Film: Unmatched Strength and Stability

Ionoplast interlayer films represent a newer and advanced option for high-strength interlayer film for safety glass. With exceptional rigidity and strength, Ionoplast films are specifically engineered for extreme safety and structural applications.

l High Strength and Rigidity: Ionoplast films provide unparalleled impact resistance, making them ideal for high-security applications. This rigidity ensures that laminated glass can withstand significant forces, which is particularly beneficial in areas where hurricanes, vandalism, or forced entry may pose risks.

l Superior Moisture and UV Resistance: Unlike PVB, Ionoplast film maintains its integrity even in wet or high UV environments. This durability makes it a highly reliable choice for both indoor and outdoor applications where environmental factors are a concern.

l Thin Profile for High Performance: Despite its high strength, Ionoplast film can be applied in thin layers, reducing the weight of the glass panel while maintaining high impact resistance. This feature makes it ideal for both architectural and automotive uses, where weight and strength must be balanced.

Ionoplast is generally more expensive than both EVA and PVB but offers enhanced strength, making it worth the investment for projects that demand the highest level of safety.

Best Applications: Ionoplast is ideal for hurricane-resistant glass, security windows, and structural glass applications in high-rise buildings or other critical areas where impact resistance and structural integrity are non-negotiable.

Choosing the Right High-Strength Interlayer Film for Safety Glass

When selecting the right interlayer film for safety glass, it’s essential to consider factors such as environmental conditions, impact resistance, and clarity requirements. Each film type—EVA, PVB, and Ionoplast—has unique strengths and limitations, and the best choice will depend on the specific application and safety needs.

- For UV Exposure and Cost-Effectiveness: EVA film is an excellent choice for applications that require durability against UV exposure, making it suitable for facades, solar panels, and other outdoor uses.

- For High Impact and Noise Reduction: PVB film offers high impact resistance and sound insulation, which makes it a strong option for automotive and architectural glass in noise-sensitive or high-traffic areas.

- For Maximum Safety and Structural Applications: Ionoplast film is ideal for high-security or structural applications, where impact resistance and longevity in extreme conditions are essential.

By understanding the strengths of each interlayer option, you can choose a high-strength interlayer film for safety glass that meets your project’s safety and durability requirements. At Suzhou Xiaoshi Technology Co., Ltd., we are dedicated to providing top-quality EVA, PVB, and Ionoplast films, helping clients achieve optimal safety and performance in every glass application. Reach out to our team today to find the best solution for your glass lamination needs.