switchable Film Installation Instruction

Before you start the installation work, Please read these instructions carefully and be sure to follow all the steps involved. If you still have question, please contact us.

1. How to handle PDLC film

· Never fold or make curve on the film

· The film must be kept loosely rolled or flat all the time

· When you move the film , please keep it parallel, it is best to have two people

move larger sheets to reduce the risk of damage.

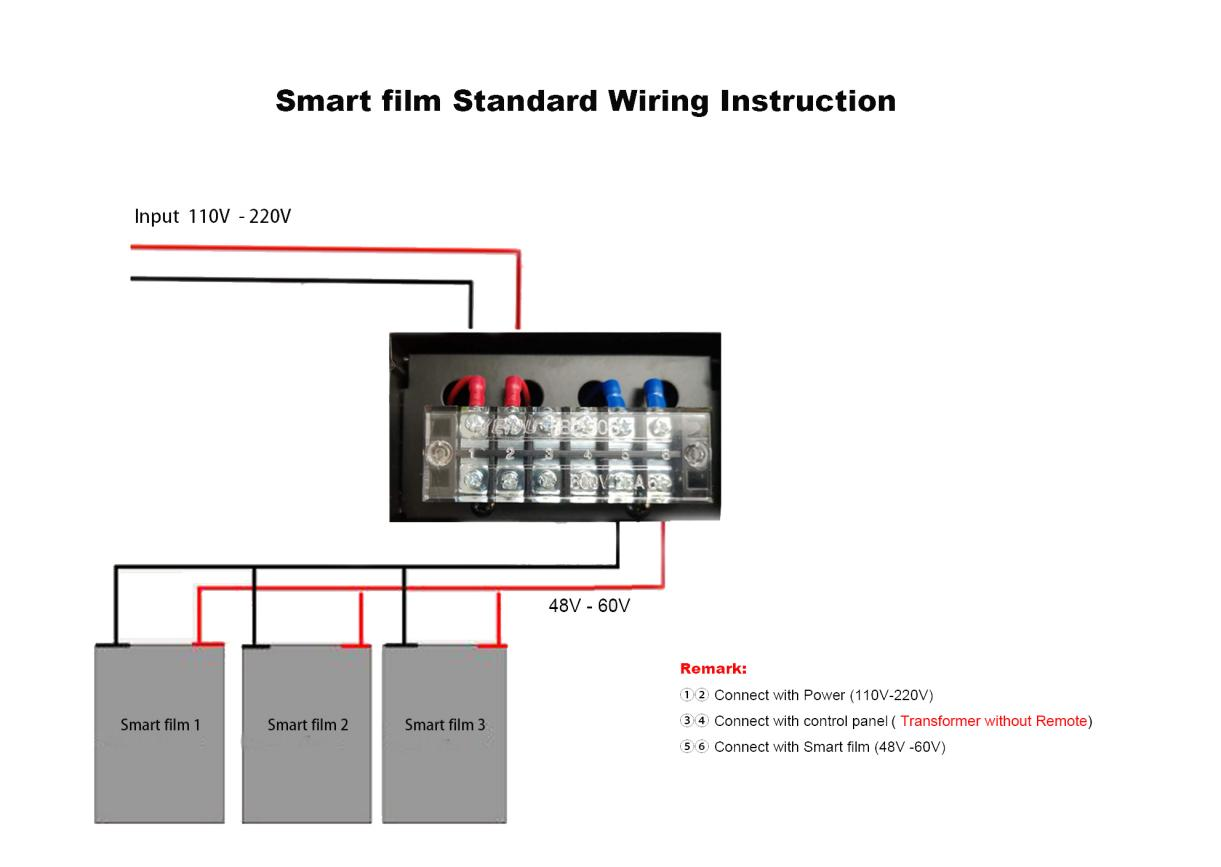

2, How to connect transformer

·Transformer must be connected before connect with power. Otherwise, high voltage will cause irreversible damage.

·Transformer size : 50W/100W/200W/300W, dimmer or remote control. (Touch and App control)

3, How to connect multiple pieces of smart films or smart glasses

4 , Edge sealing

The edge and the busbar position must be sealed with special silicon glue to protect the liquid crystal molecules from oxidation.

5, Batteries is hard for international delivery. Please search the battery for remote controller after packaged delivery.

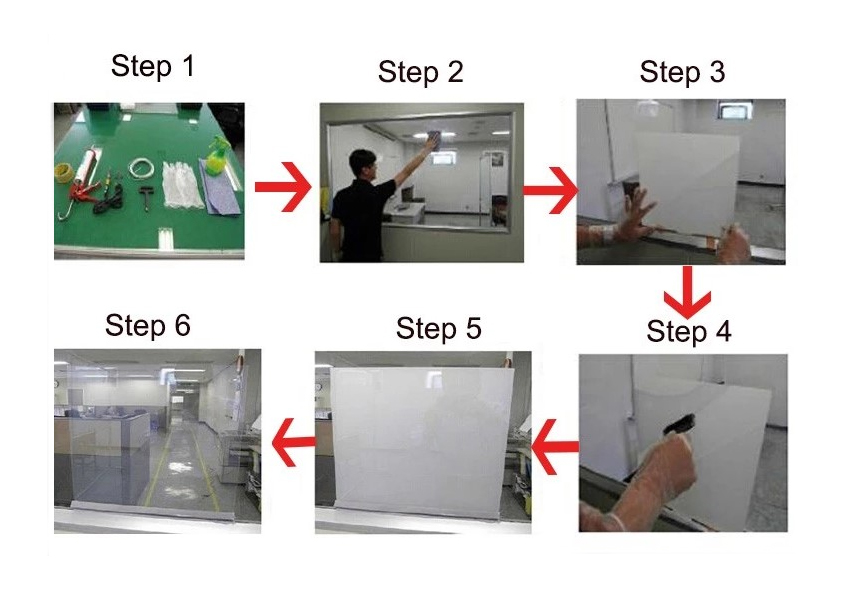

6, Instruction to install the film

1, We never allow clients cut the smart film at random

2, Power test before installation

3, We suggest skilled workers operate to avoid bubbles

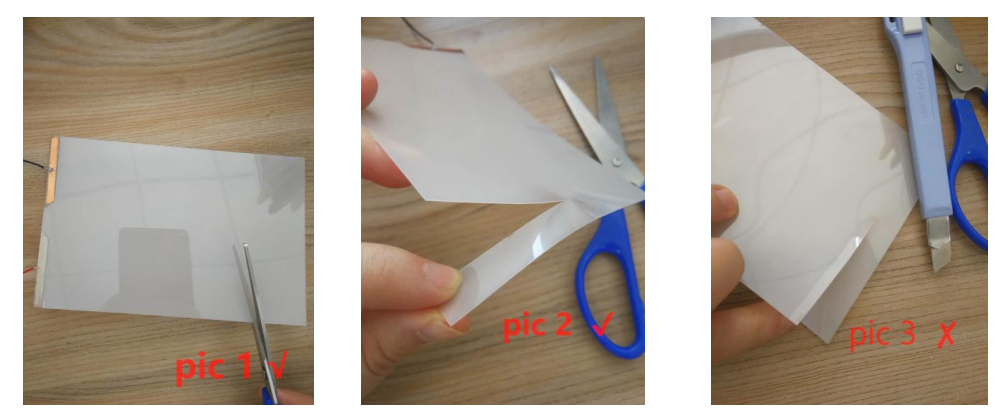

7, Film cutting guidance

We do not suggest customers to cut the film after we finished the busbar & electrode, But if there are cases must cut it, please refer to the following points.

1, Test the film , to make sure it is of no problem in quality

2, Draw the pattern you want on the paper with a thin marker

3, Tread the film with a sharp scissors, avoid to cut on the electrode.

4, The trimmed edges must be smooth , otherwise , cause high haze .

5, remember to seal the position of electrode with neutral silicon, it is very improtant.

8, Care and Maintenance

Please maintain and care for as outlined below:

1, Use soft dry microfiber cloth to wipe down the film surface,never use abrasive or chemical cleaners on the film

2, Avoid abrasively cleaning the edges of the film to mitigate possible damage.

3, Do not let metal or liquids come into the copper mesh position,This will cause PDLC film damaged.