The Best PVB Interlayer Film for Your Needs

When it comes to creating high-performance laminated glass, the choice of interlayer film is crucial. Polyvinyl butyral (PVB) interlayer film is a popular choice due to its versatility and safety benefits. But with a variety of PVB films available, choosing the right one can be challenging. This article will guide you through the different types of PVB interlayer films and help you determine the best option for your specific needs.

Understanding PVB Interlayer Film

PVB interlayer film is a tough, transparent plastic sheet placed between two sheets of glass during the lamination process. It binds the glass together, providing strength and safety. When the laminated glass is broken, the glass fragments adhere to the PVB, reducing the risk of injury from sharp shards.

Types of PVB Interlayer Film

Transparent clear PVB film: This is the most common type of PVB film, offering good adhesion and safety. It is suitable for a wide range of applications, including automotive glass and architectural glazing.

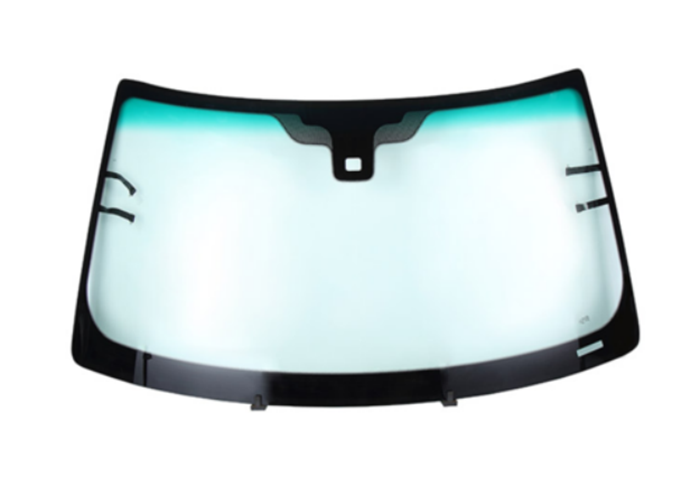

High-Performance PVB film for Car windshield: Designed for applications requiring enhanced performance, high-performance PVB films offer improved strength, durability, and resistance to environmental factors.

Hight transparent PVB film: This type of PVB film has a reduced iron content, resulting in higher light transmittance and a clearer view. It is ideal for applications where visual clarity is critical, such as display cases and museum exhibits.

Sound Control PVB: These films are formulated to reduce noise transmission, making them suitable for applications in noisy environments, such as airports and factories.

Factors to Consider When Choosing PVB film

Safety: The primary function of PVB is to hold glass together in case of breakage. Ensure the chosen PVB meets the required safety standards for your application.

Clarity: If visual clarity is important, consider low-iron PVB for maximum light transmission.

Solar Control: For applications where solar heat gain is a concern, solar control PVB can help to reduce energy costs.

Sound Control: If noise reduction is a priority, sound control PVB can help to create a quieter environment.

Durability: Choose a PVB that can withstand the environmental conditions and expected lifespan of the laminated glass.

Selecting the right PVB interlayer film is a critical decision that can impact the performance and safety of your laminated glass. By understanding the different types of PVB and considering the factors discussed above, you can make an informed choice. If you need further assistance, welcome to contact us at info@sourceglas.com