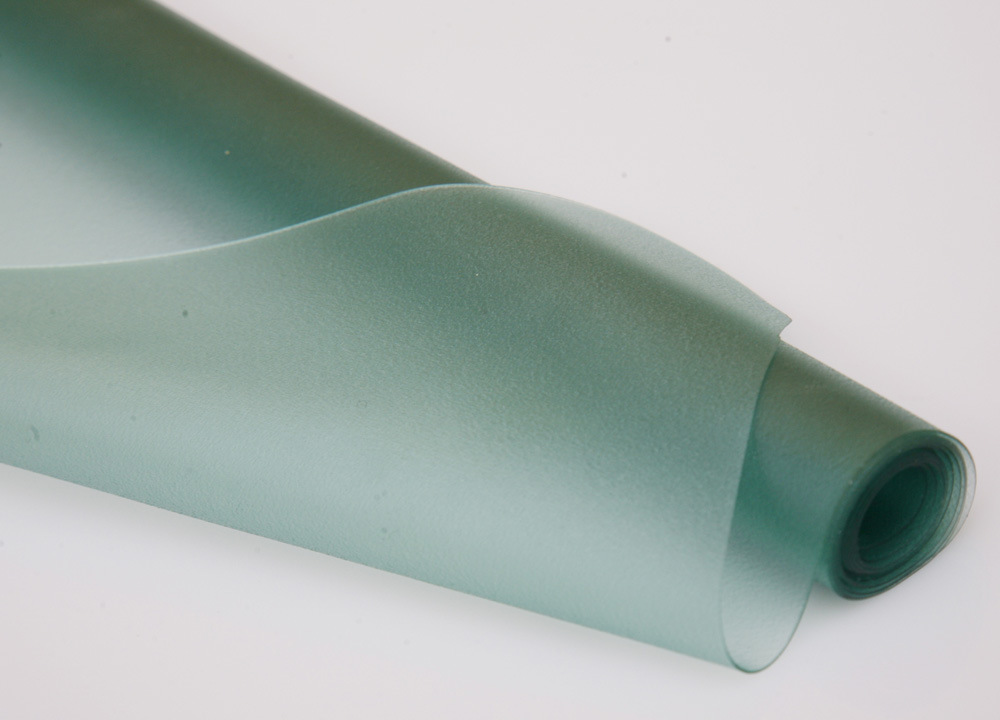

PVB Interlayer Film: A Key Material for Laminated Safety Glass

Laminated safety glass is made up of two or more layers of glass that are held together by a thin coating of PVB (polyvinyl butyral). PVB is a synthetic resin with outstanding adhesive, penetration, and impact resistance qualities. When laminated glass is damaged, the PVB film binds the glass shards together, preventing them from shattering into sharp bits that might injure or hurt people. PVB film also provides protection against infrared rays, noise, ultraviolet rays, and other risks for laminated glass. PVB film may also improve the look and functionality of laminated glass by providing a variety of colors and gradient patterns.

PVB interlayer film is widely utilized in a variety of applications that demand safety and security. PVB film, for example, is utilized in the automobile industry for windshields, side door windows, head-up displays, and panoramic roofs. By minimizing heat transfer, enhancing sound insulation, permitting clear pictures, and producing sky view glass roofs, PVB film may increase the efficiency, performance, and safety of vehicles. PVB film is used in the architecture sector for facades, balustrades, overhead glass, floors, and staircases. By providing varied colors and designs, lowering noise pollution, blocking UV rays, and boosting structural strength, PVB film may improve the aesthetics, comfort, and longevity of buildings.

PVB interlayer film is a vital material for laminated safety glass that provides several benefits in a variety of applications. PVB interlayer film is a dependable and adaptable material that can suit the demands of clients all around the world.